Stay Ahead of Damage: Crucial Upkeep Tips for Undercarriage Parts

Stay Ahead of Damage: Crucial Upkeep Tips for Undercarriage Parts

Blog Article

Make The Most Of Performance With Sturdy Undercarriage Parts

In the world of heavy machinery and devices, the role of undercarriage parts is critical in making certain optimal performance and durability. The effectiveness and efficiency of these parts can significantly influence the overall operation of machinery, making the selection of resilient undercarriage parts a critical choice for operators and managers alike.

Advantages of Utilizing Sturdy Undercarriage Components

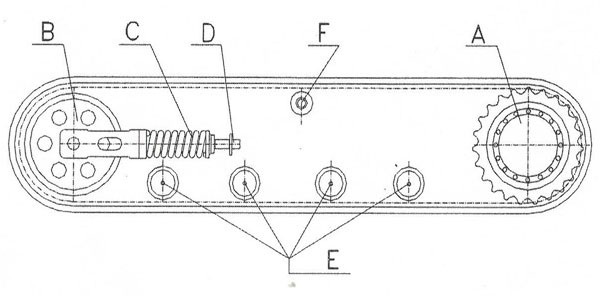

Making use of durable undercarriage components not just boosts the long life of hefty equipment yet additionally decreases upkeep prices dramatically. By purchasing high-grade undercarriage parts, such as tracks, rollers, idlers, and gears, devices operators can experience boosted uptime and enhanced overall performance.

In addition, the longevity of heavy equipment is directly linked to the quality of its undercarriage components. Resilient elements can hold up against the roughness of demanding applications, making sure that the equipment continues to be functional for extended periods. As an outcome, drivers can prevent expensive downtime and maintenance expenditures, eventually optimizing the roi for their machinery.

Elements Influencing Undercarriage Resilience

The durability of undercarriage parts in hefty equipment is affected by numerous essential aspects that straight impact efficiency and longevity. One of the vital aspects affecting undercarriage resilience is the top quality of materials used in production. High-grade materials, such as hard steel, are essential for withstanding the extreme problems and hefty loads that undercarriage parts undergo. Proper maintenance techniques likewise play a critical role in determining the life expectancy of undercarriage components. Normal examinations, lubrication, and prompt replacement of damaged parts can substantially extend the toughness of the undercarriage.

In addition, environmental elements can have a substantial effect on the long life of undercarriage components. Direct exposure to unpleasant products, extreme temperature levels, and severe working problems can accelerate deterioration on undercarriage parts. Selecting undercarriage parts that are especially created to stand up to these ecological challenges is essential for making sure sturdiness.

In addition, the style and design of undercarriage parts have a direct influence on their longevity. Parts that are made to disperse lots uniformly, decrease friction, and decrease stress and anxiety focus are more probable to have a much longer life expectancy - undercarriage parts. By thinking about these important aspects, equipment operators can optimize the sturdiness and performance of their undercarriage elements

Upkeep Tips for Prolonging Undercarriage Life

Applying normal maintenance regimens is necessary for expanding the life-span of undercarriage components in heavy equipment. To extend the undercarriage life, it is critical to frequently evaluate for wear and tear. On a regular you could look here basis look for loose or missing bolts, damaged rollers, or misaligned tracks, as these concerns can intensify and create more damage otherwise addressed without delay. In addition, make sure that the undercarriage is properly oiled according to supplier standards to lower friction and avoid premature wear.

Another crucial maintenance tip is to maintain the undercarriage clean from dust, rocks, and basics debris. Build-up in the undercarriage can speed up wear and deterioration, causing costly repairs. Cleaning the undercarriage after procedure in severe problems is recommended to protect against these problems.

Last but not least, tracking and recording maintenance tasks can assist in developing a proactive upkeep timetable. Keeping thorough records of repair services, replacements, and assessments can supply beneficial insights into the undercarriage's problem and efficiency over time, assisting in predicting and stopping potential failures. By complying with these upkeep pointers diligently, operators can substantially raise the resilience and performance of undercarriage components in hefty equipment.

Selecting the Right Undercarriage Components

Picking proper undercarriage components is critical for maximizing the efficiency and durability of heavy equipment. When it comes to choosing the appropriate undercarriage elements, there are several aspects to think about.

In addition, thinking about the top quality and track record of the producer is vital. Selecting trustworthy brands recognized for generating high-performance and sturdy undercarriage parts can significantly affect the overall efficiency and long life of the machinery. Making certain that the elements are compatible with the equipment version and properly mounted is crucial for optimum performance. By carefully selecting the right undercarriage components, devices owners can boost productivity, decrease downtime, and prolong the life-span of their hefty machinery.

Situation Research Studies: Enhanced Performance With Sturdy Parts

Including durable undercarriage components has shown significant enhancements in equipment efficiency. read this One case research study entailed a building firm that upgraded its excavator's undercarriage elements to extra resilient choices.

In an additional instance, a mining operation replaced the undercarriage components of its excavator with top quality, long lasting alternatives. This switch caused an impressive improvement in the bulldozer's maneuverability and total efficiency. The machine could navigate difficult surfaces extra successfully, leading to enhanced operational effectiveness and minimized gas intake.

Additionally, a logging business purchased long lasting undercarriage components for its forestry devices. The updated parts showed long term life-span and increased resistance to abrasion from harsh terrain. Consequently, the company experienced reduced maintenance costs and improved equipment uptime, ultimately boosting its lower line. These case researches underscore the tangible advantages of making use of long lasting undercarriage components in enhancing machinery efficiency and long life.

Final Thought

Finally, utilizing sturdy undercarriage components can substantially improve efficiency and long life of hefty machinery. Factors such as correct maintenance and picking the ideal elements play a vital role in optimizing undercarriage longevity. By applying these techniques, businesses can minimize downtime, increase effectiveness, and ultimately conserve on operational prices. Situation studies have actually revealed that spending in resilient undercarriage components can result in boosted total efficiency and productivity in different industries.

The effectiveness and efficiency of these parts can considerably affect the total operation of machinery, making the choice of sturdy undercarriage components a vital choice for operators and managers alike.Integrating sturdy undercarriage parts has demonstrated considerable improvements in equipment efficiency. These instance studies highlight the concrete advantages of making use of durable undercarriage parts in optimizing machinery performance and longevity.

In conclusion, using long lasting undercarriage components can significantly boost efficiency and durability of heavy machinery (undercarriage parts). Situation research studies have shown that investing in durable undercarriage components can lead to enhanced general performance and productivity in various sectors

Report this page